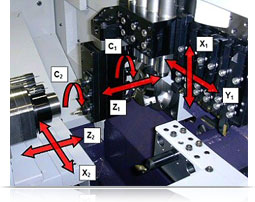

CAMWorks Mill-Turn (Live-C) Machining

CAMWORKS MILL-TURN PROVIDES A SOLUTION FOR BOTH MILLING AND TURNING ON THE SAME MACHINE TOOL. ALLOWING FOR INCREASED PRODUCTIVITY AND FLEXIBILITY

Reduce Part HandlingCAMWorks Mill-Turn provides a solution for both milling and turning on the same machine tool. Allowing for increased productivity and flexibility. See CAMWorks Live! |

CAMWorks Mill-Turn multi-function machining includes milling and turning capabilities for multi-tasking machine centers.

- Supports C, Y and B axis machining at compound angles.

- Supports 5 axis simultaneous machining.

Mill-Turn extends the capabilities of CAMWorks Milling and Turning

- The same Mill and Turn features identified by Automatic Feature Recognition (AFR) and defined using Interactive Feature Recognition (IFR) are supported in Mill-Turn. IFR can be used to define 3 Axis features for Y-axis milling and wrapped features for cylindrical features machined by C-axis motion.

- The operations that are generated for features are the same as the operations in CAMWorks 2.5 Axis Milling, 3 Axis Milling and Turning. These include automatic roughing, finishing, thread milling and single point (drilling, boring, reaming, tapping) cycles and all 3 Axis cycles.

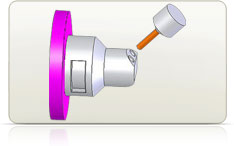

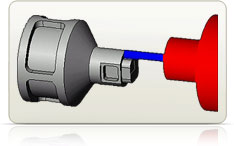

C, Y and B Axis Machining

Machining cycles are available for C, Y and B axis machining at compound angles and on the Face, ID and OD of a part.

|

|

The following mill tool axis motion is supported:

|

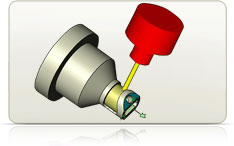

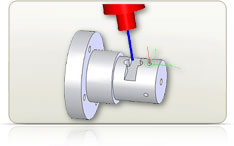

C-Axis OD (OD Free, Wrapped)

|

|

|

Y-Axis OD (OD Fixed)

|

|

|

B-Axis OD

|

|

|

Face Milling (Fixed, Free)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|